How does a manual caulking gun ensure accurate application of cartridge sealant?

Release Time : 2025-07-14

The manual caulking gun demonstrates excellent performance in ensuring accurate application of cartridge sealant, which not only relies on its sophisticated design and manufacturing process, but also benefits from the user-friendly operating experience. Through a series of innovative designs and technical applications, the manual caulking gun can help users achieve accurate and efficient sealant application in various application scenarios, thereby improving work efficiency and construction quality.

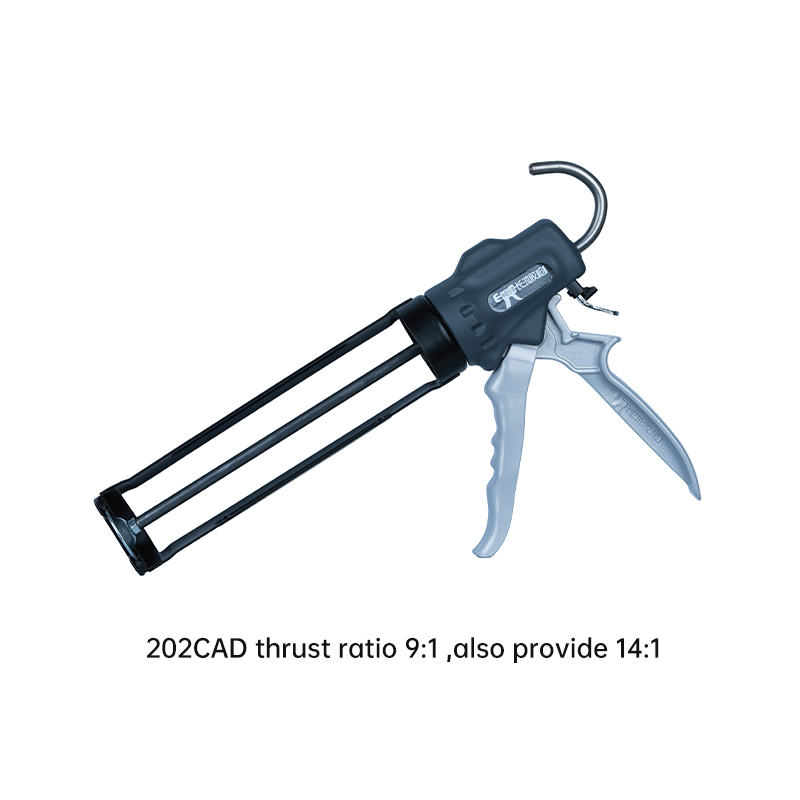

First of all, the core of the manual caulking gun lies in its unique extrusion mechanism. This tool is usually made of high-strength metal or engineering plastic to ensure a strong and durable structure. When the user presses the trigger, the internal pressure system will smoothly squeeze the sealant out of the cartridge. The key to this process is the uniform distribution of pressure. High-quality manual caulking guns are equipped with a finely tuned pressure control system to ensure consistent pressure output with each press. This means that the flow of sealant can remain stable, whether in rapid continuous operation or slow and meticulous application, so as to achieve accurate application.

Secondly, the ergonomic design of the manual caulking gun is also one of the important factors to ensure accurate application. The handle part usually adopts ergonomic shapes and materials to provide a comfortable grip and reduce fatigue caused by long-term use. In addition, the position and force adjustment function of the control lever can be adjusted according to the user's habits, making the operation more natural and smooth. These design details not only improve the user experience, but also ensure that the user can better control the force and speed during the glue application process, avoiding the problem of uneven glue volume caused by excessive force or improper operation.

In addition, the push rod and piston system of the manual caulking gun are also carefully designed to ensure the smooth flow of sealant. The push rod is usually made of high-precision processing, with a smooth surface without burrs, which can slide smoothly in the ink cartridge to prevent the sealant from clogging or stagnation. The piston is made of soft and elastic material, which fits tightly to the inner wall of the ink cartridge, effectively preventing air from entering and ensuring that each squeeze can completely empty the sealant in the ink cartridge. This seamless design not only improves the accuracy of glue application, but also maximizes the use of every drop of sealant and reduces waste.

In addition to the optimization of mechanical structure, the manual caulking gun also pays attention to accuracy in detail processing. For example, the design of the nozzle is crucial. Different models of manual caulking guns are equipped with nozzles of various sizes and shapes, which can be replaced according to specific application requirements. Slim nozzles are suitable for small spaces or occasions that require delicate work, while wide nozzles are suitable for coating large areas. These interchangeable nozzles not only increase the versatility of the tool, but also further improve the accuracy of glue application.

It is worth mentioning that the ease of operation of the manual caulking gun is also a major advantage for its accurate glue application. Without complex training or professional knowledge, anyone can quickly get started and master basic operating skills. Some high-end models are also equipped with a visual glue amount indicator or adjustment device, which allows users to control the glue output by simple observation or adjustment to ensure that each glue application achieves the expected effect. This intuitive operation method greatly reduces the possibility of misoperation, especially in work environments that require high precision.

In addition, the manual caulking gun shows great adaptability when dealing with sealants of different viscosities. Whether it is a thin liquid sealant or a thicker paste product, this tool can easily handle it. By adjusting the force of the control lever or selecting the appropriate nozzle type, users can flexibly adjust the glue speed and flow rate to meet various construction requirements. This wide applicability makes the manual caulking gun an ideal choice for various sealant applications, whether in building decoration, furniture manufacturing or industrial maintenance.

Finally, the contribution of the manual caulking gun to environmental protection cannot be ignored. With the increasing awareness of environmental protection, more and more sealant products have begun to adopt environmentally friendly formulas and do not contain volatile organic compounds (VOCs) that are harmful to the human body. As an efficient and low-loss sizing tool, the manual caulking gun can perfectly match these environmentally friendly sealants, which not only reduces the impact on the environment, but also promotes the development concept of green manufacturing. At the same time, due to its precise sizing ability, it reduces material waste caused by excessive use, further embodying the principle of sustainable development.

In summary, the manual caulking gun has shown significant advantages in ensuring the precise sizing of cartridge sealants through precise mechanical design, humanized operation experience and wide adaptability. It not only improves work efficiency and construction quality, but also plays a positive role in protecting the environment and saving resources. In the future, with the continuous advancement of technology and changes in market demand, I believe that manual caulking guns will demonstrate their unique value in more fields and provide users with better services.

First of all, the core of the manual caulking gun lies in its unique extrusion mechanism. This tool is usually made of high-strength metal or engineering plastic to ensure a strong and durable structure. When the user presses the trigger, the internal pressure system will smoothly squeeze the sealant out of the cartridge. The key to this process is the uniform distribution of pressure. High-quality manual caulking guns are equipped with a finely tuned pressure control system to ensure consistent pressure output with each press. This means that the flow of sealant can remain stable, whether in rapid continuous operation or slow and meticulous application, so as to achieve accurate application.

Secondly, the ergonomic design of the manual caulking gun is also one of the important factors to ensure accurate application. The handle part usually adopts ergonomic shapes and materials to provide a comfortable grip and reduce fatigue caused by long-term use. In addition, the position and force adjustment function of the control lever can be adjusted according to the user's habits, making the operation more natural and smooth. These design details not only improve the user experience, but also ensure that the user can better control the force and speed during the glue application process, avoiding the problem of uneven glue volume caused by excessive force or improper operation.

In addition, the push rod and piston system of the manual caulking gun are also carefully designed to ensure the smooth flow of sealant. The push rod is usually made of high-precision processing, with a smooth surface without burrs, which can slide smoothly in the ink cartridge to prevent the sealant from clogging or stagnation. The piston is made of soft and elastic material, which fits tightly to the inner wall of the ink cartridge, effectively preventing air from entering and ensuring that each squeeze can completely empty the sealant in the ink cartridge. This seamless design not only improves the accuracy of glue application, but also maximizes the use of every drop of sealant and reduces waste.

In addition to the optimization of mechanical structure, the manual caulking gun also pays attention to accuracy in detail processing. For example, the design of the nozzle is crucial. Different models of manual caulking guns are equipped with nozzles of various sizes and shapes, which can be replaced according to specific application requirements. Slim nozzles are suitable for small spaces or occasions that require delicate work, while wide nozzles are suitable for coating large areas. These interchangeable nozzles not only increase the versatility of the tool, but also further improve the accuracy of glue application.

It is worth mentioning that the ease of operation of the manual caulking gun is also a major advantage for its accurate glue application. Without complex training or professional knowledge, anyone can quickly get started and master basic operating skills. Some high-end models are also equipped with a visual glue amount indicator or adjustment device, which allows users to control the glue output by simple observation or adjustment to ensure that each glue application achieves the expected effect. This intuitive operation method greatly reduces the possibility of misoperation, especially in work environments that require high precision.

In addition, the manual caulking gun shows great adaptability when dealing with sealants of different viscosities. Whether it is a thin liquid sealant or a thicker paste product, this tool can easily handle it. By adjusting the force of the control lever or selecting the appropriate nozzle type, users can flexibly adjust the glue speed and flow rate to meet various construction requirements. This wide applicability makes the manual caulking gun an ideal choice for various sealant applications, whether in building decoration, furniture manufacturing or industrial maintenance.

Finally, the contribution of the manual caulking gun to environmental protection cannot be ignored. With the increasing awareness of environmental protection, more and more sealant products have begun to adopt environmentally friendly formulas and do not contain volatile organic compounds (VOCs) that are harmful to the human body. As an efficient and low-loss sizing tool, the manual caulking gun can perfectly match these environmentally friendly sealants, which not only reduces the impact on the environment, but also promotes the development concept of green manufacturing. At the same time, due to its precise sizing ability, it reduces material waste caused by excessive use, further embodying the principle of sustainable development.

In summary, the manual caulking gun has shown significant advantages in ensuring the precise sizing of cartridge sealants through precise mechanical design, humanized operation experience and wide adaptability. It not only improves work efficiency and construction quality, but also plays a positive role in protecting the environment and saving resources. In the future, with the continuous advancement of technology and changes in market demand, I believe that manual caulking guns will demonstrate their unique value in more fields and provide users with better services.