How does an extruction sealant tool(caulking gun) for sausage Cartridge-use to various chemicals?

Release Time : 2025-07-31

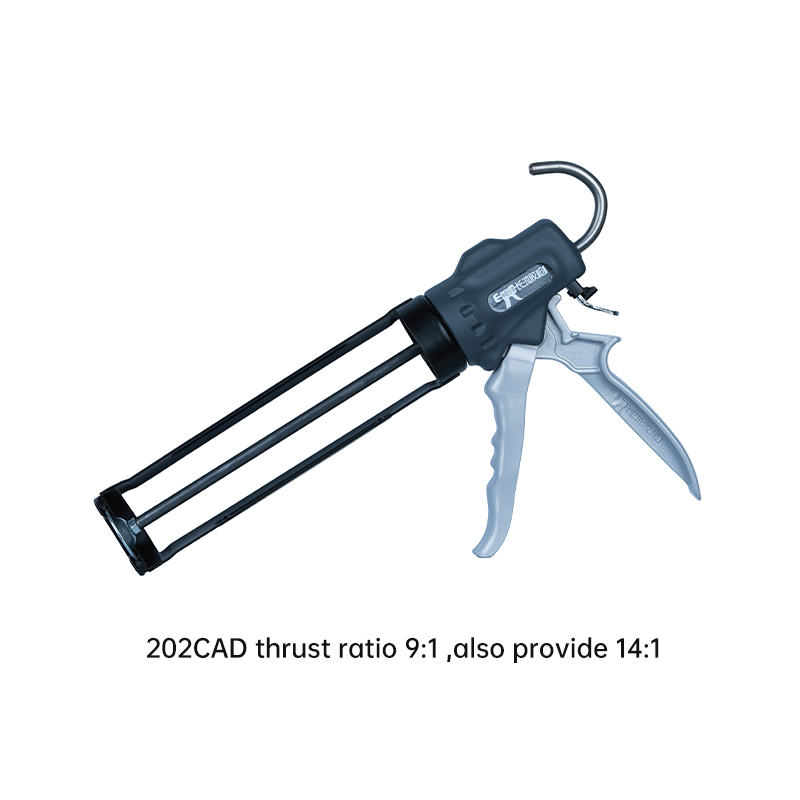

As a vital tool in construction, renovation, and industrial maintenance, the performance of an extruction sealant tool(caulking gun) for sausage cartridge-use impacts construction quality and efficiency. Caulking gun performance is particularly crucial when working with environments or materials containing chemicals.

Choosing Materials for Chemical Resistance

The main components of an extrusion sealant tool (caulking gun) include the housing, trigger, pressure regulator, and nozzle. To ensure these components maintain good performance when exposed to chemicals, manufacturers typically select materials with excellent chemical resistance. Common choices include Carbon steel, aluminum alloy, and engineering plastics such as polycarbonate and nylon.

Carbon steel is widely used in key parts of caulking guns, such as the housing and nozzle, due to its excellent corrosion resistance and mechanical strength. It effectively resists attack by acids, alkalis, solvents, and other corrosive chemicals, ensuring long-term reliability.

Aluminum alloy is another preferred material due to its lightweight and high strength. Surface treatments such as anodizing can further enhance the corrosion resistance of aluminum alloys, making them suitable for use in more complex chemical environments.

Engineering plastics, particularly specially formulated high-performance plastics such as polycarbonate and nylon, are also commonly used in certain caulking gun components. These materials offer not only excellent chemical resistance but also good abrasion and impact resistance, providing durable protection in harsh environments.

Design Features and Protection Mechanisms

In addition to the material choice, the design features of an extrusion sealant tool (caulking gun) for sausage cartridge-use largely determine its performance when exposed to chemicals. For example, many high-end models feature a closed design, minimizing direct contact between internal mechanical components and the external environment, thereby reducing the risk of chemical damage.

Some caulking guns also feature special protection mechanisms, such as drip-proof designs and automatic shut-off valves. The drip-proof design prevents residual sealant from dripping after use and contaminating the work area, while the automatic shut-off valve quickly shuts off the sealant flow path when not in use, reducing the potential for chemical reactions caused by exposure to air.

Some caulking guns also feature replaceable nozzles, allowing users to choose from different materials based on specific work requirements. For example, when working with strong acids or bases, nozzles made of PTFE (polytetrafluoroethylene) can be used. This material offers excellent chemical resistance and effectively resists most chemicals.

Applications and Performance

Extrusion sealant tools (caulking guns) for sausage cartridge-use excel in a variety of applications, especially those involving chemicals. Here are a few typical applications and their performance:

Construction Industry: On construction sites, caulking guns often encounter materials such as cement slurry and waterproofing coatings. Due to the chemical content of these materials, ordinary tools may corrode or become damaged. However, caulking guns made of chemical-resistant materials can easily handle these issues, ensuring smooth construction.

Chemical Plant Maintenance: During routine maintenance work in chemical plants, caulking guns may come into contact with various acidic and alkaline solutions, solvents, and corrosive gases. High-quality caulking guns, with their excellent chemical resistance, can operate reliably under these harsh conditions, helping technicians complete necessary repair and maintenance tasks.

Automotive repair: During vehicle repair, caulking guns are sometimes used to apply sealants to repair car body cracks or secure parts. These sealants may contain volatile organic compounds (VOCs) or other chemicals, but the design and material selection of extrusion sealant tools (caulking guns) for sausage cartridge-use ensure they can function properly in these environments without being affected.

In summary, the use of chemically resistant materials, optimized design, and appropriate protective mechanisms ensure that extruction sealant tool(caulking gun) for sausage cartridge-use perform well in the face of various chemical exposures. Whether dealing with construction materials on a construction site or corrosive chemicals in a chemical plant, a high-quality caulking gun provides reliable protection.

Choosing Materials for Chemical Resistance

The main components of an extrusion sealant tool (caulking gun) include the housing, trigger, pressure regulator, and nozzle. To ensure these components maintain good performance when exposed to chemicals, manufacturers typically select materials with excellent chemical resistance. Common choices include Carbon steel, aluminum alloy, and engineering plastics such as polycarbonate and nylon.

Carbon steel is widely used in key parts of caulking guns, such as the housing and nozzle, due to its excellent corrosion resistance and mechanical strength. It effectively resists attack by acids, alkalis, solvents, and other corrosive chemicals, ensuring long-term reliability.

Aluminum alloy is another preferred material due to its lightweight and high strength. Surface treatments such as anodizing can further enhance the corrosion resistance of aluminum alloys, making them suitable for use in more complex chemical environments.

Engineering plastics, particularly specially formulated high-performance plastics such as polycarbonate and nylon, are also commonly used in certain caulking gun components. These materials offer not only excellent chemical resistance but also good abrasion and impact resistance, providing durable protection in harsh environments.

Design Features and Protection Mechanisms

In addition to the material choice, the design features of an extrusion sealant tool (caulking gun) for sausage cartridge-use largely determine its performance when exposed to chemicals. For example, many high-end models feature a closed design, minimizing direct contact between internal mechanical components and the external environment, thereby reducing the risk of chemical damage.

Some caulking guns also feature special protection mechanisms, such as drip-proof designs and automatic shut-off valves. The drip-proof design prevents residual sealant from dripping after use and contaminating the work area, while the automatic shut-off valve quickly shuts off the sealant flow path when not in use, reducing the potential for chemical reactions caused by exposure to air.

Some caulking guns also feature replaceable nozzles, allowing users to choose from different materials based on specific work requirements. For example, when working with strong acids or bases, nozzles made of PTFE (polytetrafluoroethylene) can be used. This material offers excellent chemical resistance and effectively resists most chemicals.

Applications and Performance

Extrusion sealant tools (caulking guns) for sausage cartridge-use excel in a variety of applications, especially those involving chemicals. Here are a few typical applications and their performance:

Construction Industry: On construction sites, caulking guns often encounter materials such as cement slurry and waterproofing coatings. Due to the chemical content of these materials, ordinary tools may corrode or become damaged. However, caulking guns made of chemical-resistant materials can easily handle these issues, ensuring smooth construction.

Chemical Plant Maintenance: During routine maintenance work in chemical plants, caulking guns may come into contact with various acidic and alkaline solutions, solvents, and corrosive gases. High-quality caulking guns, with their excellent chemical resistance, can operate reliably under these harsh conditions, helping technicians complete necessary repair and maintenance tasks.

Automotive repair: During vehicle repair, caulking guns are sometimes used to apply sealants to repair car body cracks or secure parts. These sealants may contain volatile organic compounds (VOCs) or other chemicals, but the design and material selection of extrusion sealant tools (caulking guns) for sausage cartridge-use ensure they can function properly in these environments without being affected.

In summary, the use of chemically resistant materials, optimized design, and appropriate protective mechanisms ensure that extruction sealant tool(caulking gun) for sausage cartridge-use perform well in the face of various chemical exposures. Whether dealing with construction materials on a construction site or corrosive chemicals in a chemical plant, a high-quality caulking gun provides reliable protection.