Why can a exTrucTion Sealant Tool(Caulking Gun) For Sausage Cartridge-use significantly reduce adhesive waste and achieve more precise adhesive dispensing control?

Release Time : 2025-09-25

Adhesive materials are essential auxiliary materials in construction processes such as building renovation, home caulking, and waterproofing and sealing. However, traditional manual application or simple extrusion methods often lead to problems such as uneven adhesive control, discontinuous coating, and overflow at corners, which not only affects aesthetics but also results in significant material waste. The exTrucTion Sealant Tool(Caulking Gun) For Sausage Cartridge-use, as a specialized adhesive dispensing tool, effectively addresses this challenge with its scientific structural design and mechanical principles, becoming a key device for improving efficiency, saving costs, and ensuring quality in modern sealing construction. Its ability to significantly reduce adhesive waste and achieve precise adhesive dispensing control is primarily due to its comprehensive advantages in mechanical transmission, structural design, operational feedback, and material compatibility.

1. Scientific Lever Principle for Effortless and Precise Control

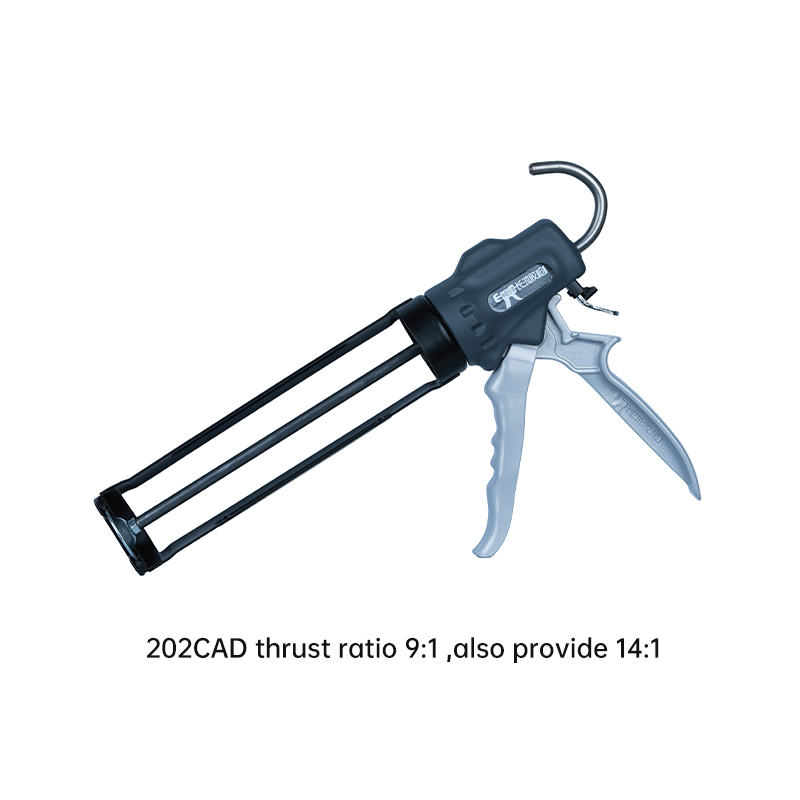

The caulking gun's core operating principle is based on lever mechanics. When the operator pulls the trigger, the force applied by the hand is transmitted to the push rod through a linkage mechanism, pushing the hose piston forward, thereby squeezing the adhesive evenly out of the dispensing nozzle. This mechanical transmission structure has been meticulously calculated to achieve a high "thrust ratio"—meaning that less hand force can generate greater thrust, enabling smooth extrusion of even high-viscosity adhesives. More importantly, this force transmission is linear and controllable: the operator can precisely adjust the adhesive delivery speed and flow rate by subtly varying the pressure of their fingers. Compared to the "loose and tight" or sudden bursts of adhesive when squeezing a hose by hand, the caulking gun achieves precise control with "stop-and-go" and flexible retraction and extension, fundamentally eliminating the risk of adhesive splashing or accumulation caused by excessive force.

2. Stable propulsion system ensures uniform and continuous adhesive delivery

Conventional extrusion methods often result in uneven force at the front of the adhesive, resulting in "more at the front and less at the back" or intermittent delivery. This not only affects sealing effectiveness but also requires repeated refilling, indirectly increasing consumables. The caulking gun's push rod, however, is designed for linear advancement, maintaining a high degree of parallelism with the hose axis, ensuring uniform pressure applied to the piston or the end of the adhesive. This stable propulsion method ensures that the adhesive is extruded from the nozzle at a constant flow rate, forming a consistent, continuous, and complete adhesive line. This ensures uniform coating across both straight seams and curved edges, reducing unnecessary effort in patching, trimming, or rework.

3. Adjustable limit and quick-lock mechanism for enhanced operational precision

High-end caulking guns are often equipped with an adjustable baffle and lock mechanism. The baffle limits the stroke of the push rod, accommodating hoses of varying lengths and preventing excessive push rod extension, which could damage the tool or hinder operation. The lock mechanism allows the user to secure the push rod position during work pauses, preventing continued flow of adhesive due to weight or pressure. This design is particularly useful when working with complex joints or changing hoses, avoiding waste caused by "empty squeeze" or "drips." Some caulking guns also feature a fine-adjustment knob for the glue output, allowing preset glue pressure, further enhancing accuracy for different glue types.

4. Dedicated Glue Dispensing Nozzle Design Optimizes Coating Pattern

The caulking gun is designed for use with a dedicated plastic or metal dispensing nozzle. Users can choose nozzles with varying diameters or bevel angles based on gap width, depth, and application requirements. Adjusting the nozzle angle allows for precise control of the glue line's shape and direction, making it particularly suitable for delicate applications around corners, edges, or narrow areas. Precise coating ensures that the glue completely fills the gap, preventing excess spillage onto the tile or wall surface, significantly reducing the difficulty of cleanup and material loss. In contrast, nozzleless or wide-diameter extruders often result in significant glue spillage, resulting in waste when scraped off during trimming.

5. Compatible with a Wide Range of Adhesives, Reducing the Risk of Material Loss

The caulking gun is compatible with a wide range of viscous materials, including silicone adhesives, epoxy caulking agents, polyurethane sealants, and foam adhesives. Its structural design is optimized for high-viscosity media, eliminating issues such as "missing" or "wasting half the gun" due to insufficient thrust. Many electric caulking guns also feature stepless speed regulation, adjusting the feed speed based on the viscosity of the adhesive. This ensures smooth dispensing of all materials, maximizes the use of each hose, and minimizes residue.

In summary, the exTrucTion Sealant Tool(Caulking Gun) For Sausage Cartridge-use, through its lever-less structure, stable feed system, precise control mechanism, adjustable stopper design, and specialized nozzle, enables precise management of adhesive delivery. This not only improves application efficiency and aesthetics, but more importantly, significantly reduces adhesive waste by minimizing spillage, dripping, rework, and residue. With material costs rising, using a professional caulking gun is not only a technological upgrade but also an economical, environmentally friendly, and efficient construction option.

1. Scientific Lever Principle for Effortless and Precise Control

The caulking gun's core operating principle is based on lever mechanics. When the operator pulls the trigger, the force applied by the hand is transmitted to the push rod through a linkage mechanism, pushing the hose piston forward, thereby squeezing the adhesive evenly out of the dispensing nozzle. This mechanical transmission structure has been meticulously calculated to achieve a high "thrust ratio"—meaning that less hand force can generate greater thrust, enabling smooth extrusion of even high-viscosity adhesives. More importantly, this force transmission is linear and controllable: the operator can precisely adjust the adhesive delivery speed and flow rate by subtly varying the pressure of their fingers. Compared to the "loose and tight" or sudden bursts of adhesive when squeezing a hose by hand, the caulking gun achieves precise control with "stop-and-go" and flexible retraction and extension, fundamentally eliminating the risk of adhesive splashing or accumulation caused by excessive force.

2. Stable propulsion system ensures uniform and continuous adhesive delivery

Conventional extrusion methods often result in uneven force at the front of the adhesive, resulting in "more at the front and less at the back" or intermittent delivery. This not only affects sealing effectiveness but also requires repeated refilling, indirectly increasing consumables. The caulking gun's push rod, however, is designed for linear advancement, maintaining a high degree of parallelism with the hose axis, ensuring uniform pressure applied to the piston or the end of the adhesive. This stable propulsion method ensures that the adhesive is extruded from the nozzle at a constant flow rate, forming a consistent, continuous, and complete adhesive line. This ensures uniform coating across both straight seams and curved edges, reducing unnecessary effort in patching, trimming, or rework.

3. Adjustable limit and quick-lock mechanism for enhanced operational precision

High-end caulking guns are often equipped with an adjustable baffle and lock mechanism. The baffle limits the stroke of the push rod, accommodating hoses of varying lengths and preventing excessive push rod extension, which could damage the tool or hinder operation. The lock mechanism allows the user to secure the push rod position during work pauses, preventing continued flow of adhesive due to weight or pressure. This design is particularly useful when working with complex joints or changing hoses, avoiding waste caused by "empty squeeze" or "drips." Some caulking guns also feature a fine-adjustment knob for the glue output, allowing preset glue pressure, further enhancing accuracy for different glue types.

4. Dedicated Glue Dispensing Nozzle Design Optimizes Coating Pattern

The caulking gun is designed for use with a dedicated plastic or metal dispensing nozzle. Users can choose nozzles with varying diameters or bevel angles based on gap width, depth, and application requirements. Adjusting the nozzle angle allows for precise control of the glue line's shape and direction, making it particularly suitable for delicate applications around corners, edges, or narrow areas. Precise coating ensures that the glue completely fills the gap, preventing excess spillage onto the tile or wall surface, significantly reducing the difficulty of cleanup and material loss. In contrast, nozzleless or wide-diameter extruders often result in significant glue spillage, resulting in waste when scraped off during trimming.

5. Compatible with a Wide Range of Adhesives, Reducing the Risk of Material Loss

The caulking gun is compatible with a wide range of viscous materials, including silicone adhesives, epoxy caulking agents, polyurethane sealants, and foam adhesives. Its structural design is optimized for high-viscosity media, eliminating issues such as "missing" or "wasting half the gun" due to insufficient thrust. Many electric caulking guns also feature stepless speed regulation, adjusting the feed speed based on the viscosity of the adhesive. This ensures smooth dispensing of all materials, maximizes the use of each hose, and minimizes residue.

In summary, the exTrucTion Sealant Tool(Caulking Gun) For Sausage Cartridge-use, through its lever-less structure, stable feed system, precise control mechanism, adjustable stopper design, and specialized nozzle, enables precise management of adhesive delivery. This not only improves application efficiency and aesthetics, but more importantly, significantly reduces adhesive waste by minimizing spillage, dripping, rework, and residue. With material costs rising, using a professional caulking gun is not only a technological upgrade but also an economical, environmentally friendly, and efficient construction option.