How to prevent colloid backflow when using an extrusion sealant tool (caulking gun) for sausage cartridges?

Release Time : 2025-09-11

When using an extrusion sealant tool (caulking gun) for sausage cartridges, fluid backflow is a common problem, primarily caused by pressure imbalance within the tool or sealing failure. Backflow not only wastes material but can also contaminate the tool, affecting subsequent precision, or even cause the fluid to solidify and clog the gun. Therefore, comprehensive prevention and control measures are necessary, encompassing tool design, operating procedures, and maintenance, to ensure a smooth and efficient caulking process.

The sealing performance of the tool itself is fundamental to preventing fluid backflow. The core sealing components of an extrusion sealant tool (caulking gun) for sausage cartridges typically include the piston, sealing ring, and nozzle connection. The sealant's fit between the piston and the inner wall of the cartridge directly impacts the sealing effect. If the piston surface is worn or scratched, fluid can easily seep into the tool's rear chamber through the gap, causing backflow. Therefore, it is crucial to select a high-quality piston material (such as wear-resistant rubber or polytetrafluoroethylene) with a smooth and elastic surface to accommodate the extrusion of fluids of varying viscosities. Furthermore, the sealing ring's material and installation position must be precisely matched. O-rings must fit into a dedicated groove to prevent displacement during extrusion; Y-rings must ensure that the opening aligns with the direction of fluid flow, forming a one-way sealing barrier.

Controlling pressure during operation is crucial for preventing backflow. When extruding a caulking gun, maintain a steady pressure and avoid sudden release or excessive force. Rapidly releasing pressure will create a momentary negative pressure within the cartridge, drawing back the extruded fluid. Especially when changing cartridges or pausing operations, slowly reduce pressure and wait until fluid flow stops before fully releasing the trigger. Furthermore, the angle of contact between the nozzle and the work surface must be carefully considered. Excessive tilt can cause gravity to backflow the fluid before it fully cures. It is recommended to keep the nozzle perpendicular to the work surface and gradually move it as the fluid is extruded to minimize fluid accumulation at the tip of the nozzle.

The choice and compatibility of the cartridge directly impact the risk of backflow. Different sizes of rubber cartridges must be matched to corresponding caulking gun models. If the cartridge diameter is too large or too long, the piston may not fully contact the inner wall, creating a blind spot in the seal. Furthermore, the fluidity of the caulking fluid itself is a crucial factor. High-viscosity caulking fluids (such as silicone sealant) have a low probability of backflow due to strong intermolecular forces. Low-viscosity caulking fluids (such as polyurethane foam) require tool design (such as adding a check valve) or operating techniques (such as staged extrusion) to prevent backflow. Before use, inspect the caulking cartridge packaging to ensure it is intact to avoid fluidity issues caused by caulking fluid deterioration or contamination.

Proper tool maintenance is crucial for long-term backflow prevention. After each use, clean any residual caulking fluid from the nozzle and piston to prevent curing and impurities from affecting sealing performance. To clean, soak the tool in a special solvent, then wipe with a soft cloth after the caulking fluid has softened. Avoid scratching the sealing surface with sharp tools, which can damage the sealing surface. Regularly inspect the seals and pistons for wear. If any signs of wear, cracking, or deformation are detected, replace them with the same model immediately. When unused for extended periods, the tool should be disassembled and cleaned, and a special lubricant should be applied to the piston surface to prevent seal failure due to drying and shrinkage of the rubber components.

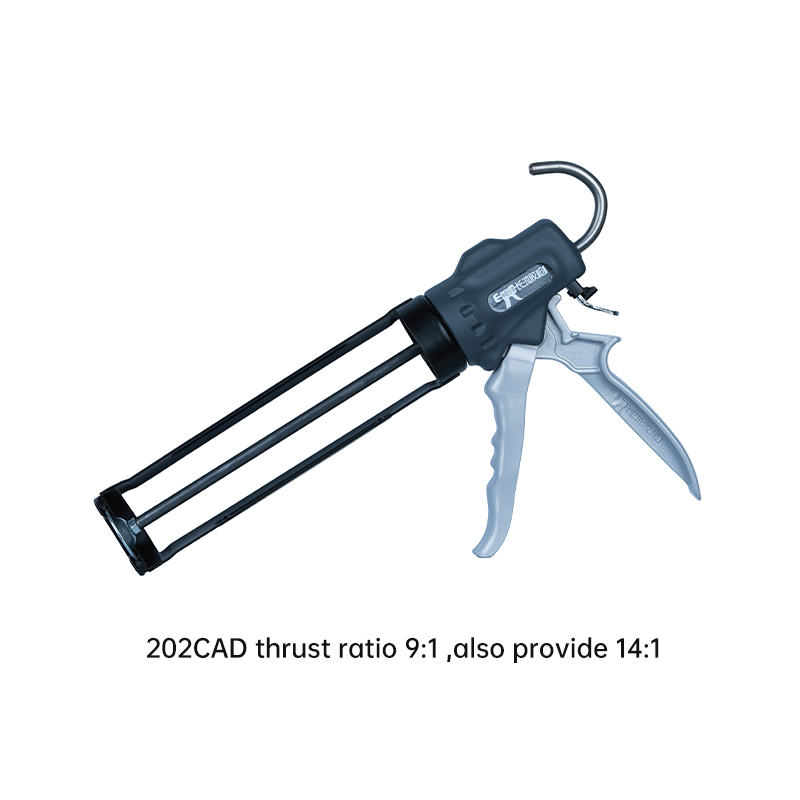

For special application scenarios, additional measures can be taken to enhance backflow prevention. For example, in high-temperature environments, the fluidity of the adhesive increases. The risk of backflow can be reduced by lowering the tool temperature (for example, wrapping the cartridge with a damp cloth) or selecting a high-temperature-resistant adhesive. When working on vertical surfaces, a "staged extrusion-rapid curing" method can be employed. This involves extruding a small amount of adhesive each time and immediately smoothing it with the tool. This utilizes the surface tension of the adhesive to form a temporary sealant layer, preventing subsequent backflow. Furthermore, some high-end caulking guns are equipped with an automatic retraction mechanism that automatically maintains pressure after the trigger is released, further reducing the possibility of backflow.

By optimizing tool design, standardizing operating procedures, ensuring strict cartridge adaptation, and performing regular maintenance, the backflow problem of extrusion sealant tools (caulking guns) for sausage cartridges can be effectively addressed. This not only improves application efficiency and material utilization, but also extends tool life, providing stable and reliable support for various sealing projects.