How does a caulking gun redefine the sealing application experience with ergonomics and efficient transmission?

Release Time : 2025-11-18

In building decoration, door and window installation, bathroom sealing, and industrial maintenance, the even, continuous, and labor-saving application of sealant is crucial for ensuring waterproof, dustproof, and aesthetically pleasing joints. As the core application tool for cartridge sealants, the manual caulking gun, despite its simple structure, embodies a delicate balance of mechanical transmission, materials engineering, and ergonomics. Modern high-performance caulking guns, with their high thrust ratio, smooth sealant control, durable construction, and comfortable grip, significantly improve application efficiency and sealant quality, becoming an indispensable and reliable partner for professional craftsmen and DIY users.

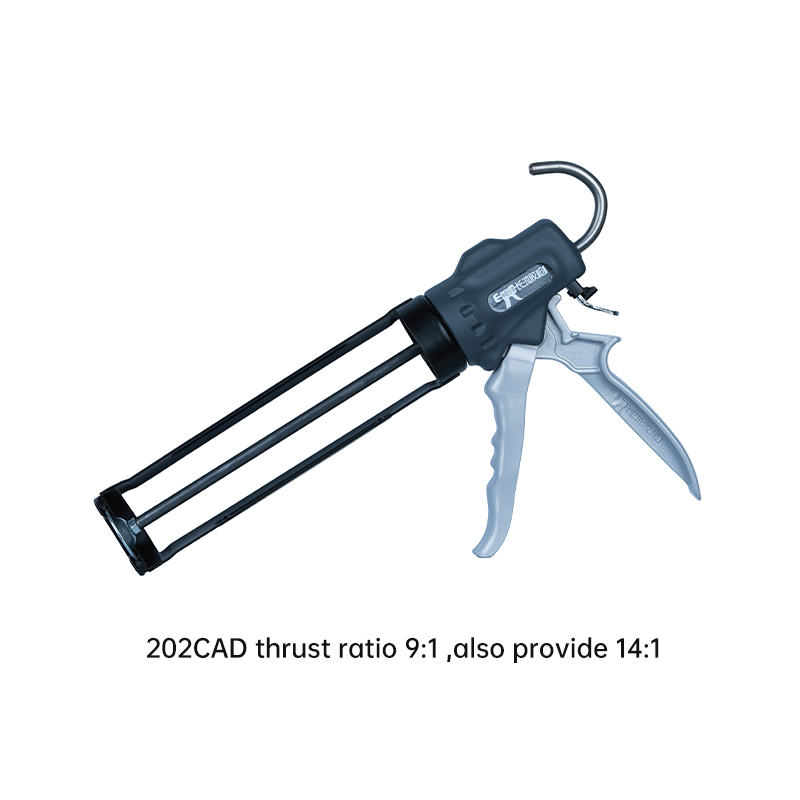

The core advantage of a caulking gun lies first in its efficient mechanical transmission system. High-quality products employ a double-bar or gear-driven pressure structure with a leverage ratio of 10:1 or higher. By optimizing the fulcrum position and push rod length, maximum thrust is generated with minimal hand force, easily handling high-viscosity silicone sealants, polyurethane sealants, and even fire-retardant sealants. The push plate flatness error is less than 0.1mm, ensuring uniform force on the glue cartridge and preventing nozzle clogging or glue breakage due to uneven pressure. The pull-back mechanism is equipped with a spring reset or quick release button, enabling "one-click zeroing" for glue cartridge replacement and significantly improving operational continuity. Some high-end models even introduce a ratchet-type propulsion mechanism, supporting one-handed fine-tuning of the glue dispensing amount for precise control of filling narrow gaps.

The structural materials balance strength and lightweight. The main frame of the gun is made of high-strength die-cast aluminum alloy or glass fiber reinforced nylon, with a weight controlled between 400-600 grams, preventing fatigue during prolonged operation. The push rod and hinge are hardened, with a bending strength exceeding 800MPa, capable of withstanding repeated high-load impacts without deformation. The glue cartridge clamp has built-in elastic buckles and anti-slip textures, accommodating standard 290ml, 310ml, and 400ml glue cartridges, ensuring a secure and non-detachable fit. All metal parts are anodized or electrophoretically coated, making them corrosion-resistant and anti-aging, maintaining smooth operation even in humid, alkaline, or oily environments.

Ergonomic design deeply optimizes the user experience. The handle contour is modeled based on the natural grip posture of the palm, wrapped with a TPE soft rubber layer for anti-slip and shock absorption, effectively distributing pressure points; the trigger travel is short and the rebound is sensitive, reducing finger fatigue; the gun's center of gravity is close to the palm, ensuring stable control and facilitating one-handed operation at heights or in confined spaces. Some professional models are also equipped with a rotating nozzle holder and an extended nozzle, easily handling complex areas such as window frame corners and pipe interfaces, achieving "point-and-shoot" freedom of operation.

Reliability and ease of maintenance are equally outstanding. The entire machine has no electronic components, a simple structure, and a near-zero failure rate; key moving joints use self-lubricating bearings, eliminating the need for regular lubrication; the contact surface between the push plate and the barrel is smooth and burr-free, preventing scratches on the aluminum liner of the glue cartridge and causing glue leakage. Even after long-term inactivity, it will still operate smoothly upon restarting, truly achieving "ready to use immediately."

Ultimately, the value of the caulking gun lies not only in "extruding glue," but also in its mechanical intelligence, delivering precision and ease with every press. When a window seam is evenly sealed, and when bathroom joints are completely leak-free, this tool silently supports professional quality. In today's era of refined architecture and widespread DIY home improvement, the high-performance caulking gun continues to define new standards for sealing applications with its combined advantages of labor-saving, precision, and durability—ensuring every drop of adhesive is applied perfectly.

The core advantage of a caulking gun lies first in its efficient mechanical transmission system. High-quality products employ a double-bar or gear-driven pressure structure with a leverage ratio of 10:1 or higher. By optimizing the fulcrum position and push rod length, maximum thrust is generated with minimal hand force, easily handling high-viscosity silicone sealants, polyurethane sealants, and even fire-retardant sealants. The push plate flatness error is less than 0.1mm, ensuring uniform force on the glue cartridge and preventing nozzle clogging or glue breakage due to uneven pressure. The pull-back mechanism is equipped with a spring reset or quick release button, enabling "one-click zeroing" for glue cartridge replacement and significantly improving operational continuity. Some high-end models even introduce a ratchet-type propulsion mechanism, supporting one-handed fine-tuning of the glue dispensing amount for precise control of filling narrow gaps.

The structural materials balance strength and lightweight. The main frame of the gun is made of high-strength die-cast aluminum alloy or glass fiber reinforced nylon, with a weight controlled between 400-600 grams, preventing fatigue during prolonged operation. The push rod and hinge are hardened, with a bending strength exceeding 800MPa, capable of withstanding repeated high-load impacts without deformation. The glue cartridge clamp has built-in elastic buckles and anti-slip textures, accommodating standard 290ml, 310ml, and 400ml glue cartridges, ensuring a secure and non-detachable fit. All metal parts are anodized or electrophoretically coated, making them corrosion-resistant and anti-aging, maintaining smooth operation even in humid, alkaline, or oily environments.

Ergonomic design deeply optimizes the user experience. The handle contour is modeled based on the natural grip posture of the palm, wrapped with a TPE soft rubber layer for anti-slip and shock absorption, effectively distributing pressure points; the trigger travel is short and the rebound is sensitive, reducing finger fatigue; the gun's center of gravity is close to the palm, ensuring stable control and facilitating one-handed operation at heights or in confined spaces. Some professional models are also equipped with a rotating nozzle holder and an extended nozzle, easily handling complex areas such as window frame corners and pipe interfaces, achieving "point-and-shoot" freedom of operation.

Reliability and ease of maintenance are equally outstanding. The entire machine has no electronic components, a simple structure, and a near-zero failure rate; key moving joints use self-lubricating bearings, eliminating the need for regular lubrication; the contact surface between the push plate and the barrel is smooth and burr-free, preventing scratches on the aluminum liner of the glue cartridge and causing glue leakage. Even after long-term inactivity, it will still operate smoothly upon restarting, truly achieving "ready to use immediately."

Ultimately, the value of the caulking gun lies not only in "extruding glue," but also in its mechanical intelligence, delivering precision and ease with every press. When a window seam is evenly sealed, and when bathroom joints are completely leak-free, this tool silently supports professional quality. In today's era of refined architecture and widespread DIY home improvement, the high-performance caulking gun continues to define new standards for sealing applications with its combined advantages of labor-saving, precision, and durability—ensuring every drop of adhesive is applied perfectly.