How does the caulking gun transform home grout sealing from a "dirty, messy, and tiring" process into a "precise and efficient" one?

Release Time : 2025-12-04

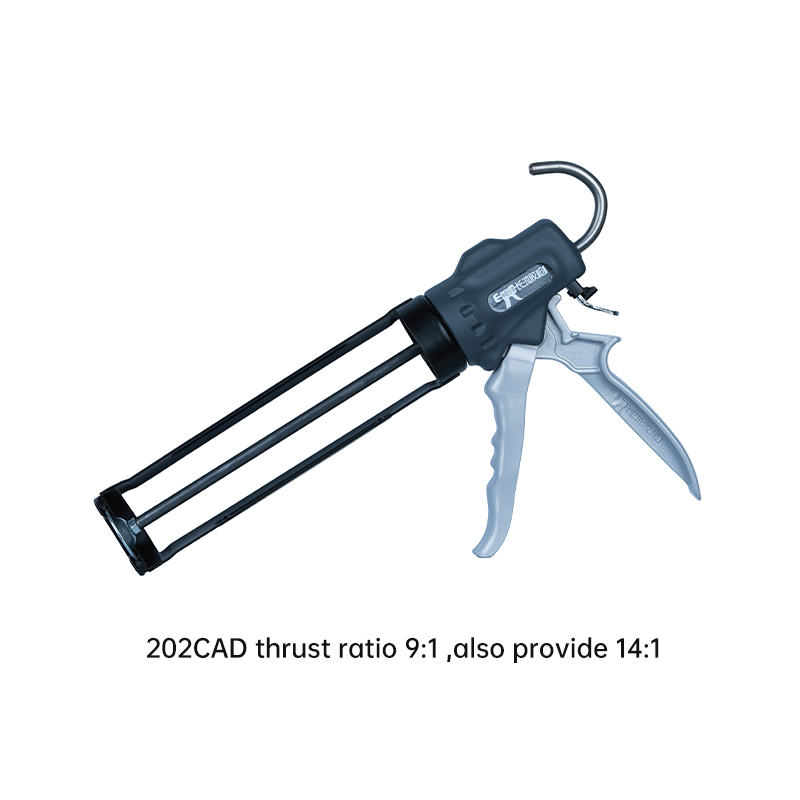

In home renovation, sealing and beautifying the joints between tiles, countertops, and window frames is a seemingly simple yet extremely prone-to-problem step. Traditional manual caulking often results in uneven caulking, intermittent application, overflow that contaminates surrounding areas, and hand pain, which is not only time-consuming and laborious but also severely affects the overall aesthetics. The caulking gun—this seemingly ordinary tool—is completely changing the grout sealing experience with its scientific mechanics design and user-friendly features, upgrading what was originally a "dirty, messy, and tiring" manual task into a "precise, labor-saving, and efficient" professional operation.

1. Lever-based labor-saving structure: Say goodbye to hand pain and tremors

The core advantage of the caulking gun lies in its lever transmission mechanism. A small grip force applied through the handle is amplified by the push rod and converted into a powerful thrust, evenly propelling the piston inside the caulking tube forward. Compared to manually squeezing the glue tube, a caulking gun saves over 60% of hand strength, significantly reducing fatigue, especially during prolonged work or when using high-viscosity sealants. High-end models also employ a double-lever or gear-driven pressure-boosting design to further enhance thrust stability and prevent inconsistent glue application due to hand tremors.

2. Precise Flow Control Design: Achieving Millimeter-Level Glue Dispensing Control

The key to successful caulking is evenness. The caulking gun features an adjustable nozzle or can be used with different sized tips, allowing users to flexibly switch between fine, angled, or flat tips to precisely control the glue line thickness according to the gap width. Some professional caulking guns also have a flow limit knob or push-rod locking device to prevent glue from continuing to seep out due to gravity or residual pressure when paused, effectively avoiding dripping and trailing. This precise control results in a full, continuous glue line with neat edges, significantly reducing subsequent smoothing and cleaning work.

3. Ergonomic Optimization: Enhancing Operational Comfort and Efficiency

The caulking gun is designed with ergonomics in mind in its handle curvature, grip angle, and materials. The non-slip rubber wrap and hand-shaped design not only improve grip stability but also distribute pressure and reduce wear on the thumb and forefinger. The lightweight engineering plastic body reduces overall weight, facilitating prolonged one-handed operation; while the push rod's spring-back design allows for smoother continuous application of sealant. These details collectively improve the construction rhythm, enabling even lengthy grouting projects to be completed in one go.

4. Strong Adaptability: One Gun for Multiple Adhesives and Scenarios

The caulking gun is compatible with a variety of commonly used home improvement materials, including silicone sealant, grout, structural adhesive, and expanding foam. Whether it's sealing kitchen countertops for mold prevention, grouting bathroom tiles, finishing window frames, or filling floor expansion joints, one caulking gun can handle all your needs. Some electric caulking guns even support stepless speed adjustment, allowing you to control the dispensing speed with a button for precise "point-and-shoot" application, making them especially suitable for beginners or those working on delicate areas.

5. Clean Application: Reducing Pollution and Waste at the Source

Because the adhesive is completely sealed within the cartridge and dispensed only through the nozzle, the caulking gun fundamentally prevents adhesive from spilling onto hands or tools. With a dedicated scraper or damp cloth, a smooth, even caulking finish is achieved with simple touch-ups after application, eliminating the need for repeated wiping and cleaning. Precise dispensing also reduces adhesive waste; one tube can cover a longer gap, making it economical and environmentally friendly.

Though small, the caulking gun is a key tool for upgrading home grout sealing techniques. It transforms manual labor into a controllable and predictable technical operation, improving not only construction efficiency and finished product quality but also allowing ordinary users to easily achieve near-professional-level sealing results. In today's pursuit of detail, quality, and efficient living, a good caulking gun is the ideal assistant for achieving "refined home living, starting with the grout lines."

1. Lever-based labor-saving structure: Say goodbye to hand pain and tremors

The core advantage of the caulking gun lies in its lever transmission mechanism. A small grip force applied through the handle is amplified by the push rod and converted into a powerful thrust, evenly propelling the piston inside the caulking tube forward. Compared to manually squeezing the glue tube, a caulking gun saves over 60% of hand strength, significantly reducing fatigue, especially during prolonged work or when using high-viscosity sealants. High-end models also employ a double-lever or gear-driven pressure-boosting design to further enhance thrust stability and prevent inconsistent glue application due to hand tremors.

2. Precise Flow Control Design: Achieving Millimeter-Level Glue Dispensing Control

The key to successful caulking is evenness. The caulking gun features an adjustable nozzle or can be used with different sized tips, allowing users to flexibly switch between fine, angled, or flat tips to precisely control the glue line thickness according to the gap width. Some professional caulking guns also have a flow limit knob or push-rod locking device to prevent glue from continuing to seep out due to gravity or residual pressure when paused, effectively avoiding dripping and trailing. This precise control results in a full, continuous glue line with neat edges, significantly reducing subsequent smoothing and cleaning work.

3. Ergonomic Optimization: Enhancing Operational Comfort and Efficiency

The caulking gun is designed with ergonomics in mind in its handle curvature, grip angle, and materials. The non-slip rubber wrap and hand-shaped design not only improve grip stability but also distribute pressure and reduce wear on the thumb and forefinger. The lightweight engineering plastic body reduces overall weight, facilitating prolonged one-handed operation; while the push rod's spring-back design allows for smoother continuous application of sealant. These details collectively improve the construction rhythm, enabling even lengthy grouting projects to be completed in one go.

4. Strong Adaptability: One Gun for Multiple Adhesives and Scenarios

The caulking gun is compatible with a variety of commonly used home improvement materials, including silicone sealant, grout, structural adhesive, and expanding foam. Whether it's sealing kitchen countertops for mold prevention, grouting bathroom tiles, finishing window frames, or filling floor expansion joints, one caulking gun can handle all your needs. Some electric caulking guns even support stepless speed adjustment, allowing you to control the dispensing speed with a button for precise "point-and-shoot" application, making them especially suitable for beginners or those working on delicate areas.

5. Clean Application: Reducing Pollution and Waste at the Source

Because the adhesive is completely sealed within the cartridge and dispensed only through the nozzle, the caulking gun fundamentally prevents adhesive from spilling onto hands or tools. With a dedicated scraper or damp cloth, a smooth, even caulking finish is achieved with simple touch-ups after application, eliminating the need for repeated wiping and cleaning. Precise dispensing also reduces adhesive waste; one tube can cover a longer gap, making it economical and environmentally friendly.

Though small, the caulking gun is a key tool for upgrading home grout sealing techniques. It transforms manual labor into a controllable and predictable technical operation, improving not only construction efficiency and finished product quality but also allowing ordinary users to easily achieve near-professional-level sealing results. In today's pursuit of detail, quality, and efficient living, a good caulking gun is the ideal assistant for achieving "refined home living, starting with the grout lines."