From tiles to curtain walls, how do cartridge-based extruction sealant tool(caulking gun) for cartridge use withstand high pressure and high viscosity materials?

Release Time : 2025-08-27

In modern architectural decoration projects, caulking has long since expanded beyond simple caulking of household tiles. From residential bathrooms to commercial plaza floors to the structural sealing of glass curtain walls in high-rise buildings, the application of caulking materials is becoming increasingly complex, posing extruction sealant tool(caulking gun) for cartridge use. Especially when working with high-viscosity materials like silicone adhesives, polyurethane sealants, and epoxy resins, cartridge-based extrusion sealant tools (caulking guns) must withstand immense internal pressure while maintaining stable output.

1. Structural Design: Enhanced Force Transfer and Improved Thrust Efficiency

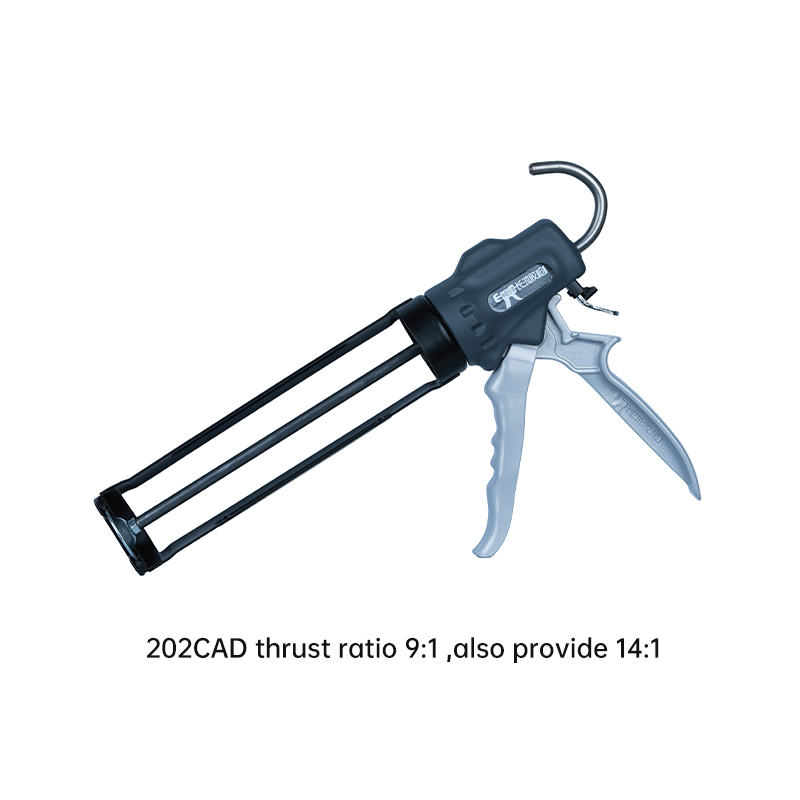

The core task of cartridge-based extrusion sealant tools (caulking guns) is to smoothly eject high-viscosity colloids from cartridges. High-viscosity materials have high flow resistance, requiring significantly more thrust than standard latex or low-viscosity caulking agents. To this end, professional-grade extrusion sealing tools (caulking guns) for cartridges generally utilize a high-strength mechanical lever structure. This scientifically designed lever ratio amplifies the operator's manual force several times.

2. Key Components: High-hardness Materials Resist Wear and Deformation

Long-term use of highly viscous materials can cause severe wear on the internal components of an extrusion sealing tool (caulking gun) for cartridges, particularly the push rod and plunger tip. Therefore, high-end extrusion sealing tools (caulking guns) for cartridges generally utilize hardened steel push rods or ceramic plunger tips. These materials have a high surface hardness (reaching HRC60 and above), are wear- and corrosion-resistant, and maintain a smooth surface even when pushing through abrasive caulk for extended periods, reducing friction and preventing "sticking." Furthermore, the gun frame is often reinforced with high-strength aluminum alloy or engineering plastic, ensuring lightweight while providing sufficient bending and compression resistance. Some curtain wall-grade electric extrusion sealing tools (caulking guns) for cartridge use even feature all-metal bodies to withstand the intense working conditions of construction sites.

3. Sealing System: Preventing High-Pressure Leakage and Ensuring Stable Pressure

Highly viscous materials often require high pressure for successful extrusion. Any pressure leakage not only affects the uniformity of the adhesive but can also cause backflow or dripping. Therefore, the sealing system of the extrusion sealing tool (caulking gun) for cartridge use is crucial.

4. Cartridge Compatibility: Optimizing Volume and Inner Diameter to Reduce Flow Resistance

The performance of an extrusion sealing tool (caulking gun) for cartridge use is closely related to the cartridge used. For high-volume, high-viscosity applications like curtain wall sealing, standard 310ml rigid aluminum tubes or plastic cartridges are typically used. Their smooth inner wall and uniform dimensions perfectly match the push rod of the extrusion sealing tool (caulking gun) for cartridge use, reducing frictional resistance. In addition, some specialized extrusion sealant tools (caulking guns) for cartridge use support two-component adhesive cartridges (such as epoxy AB adhesive). They feature a built-in static mixer and a synchronized push mechanism in the gun body, ensuring the two high-viscosity materials are extruded and mixed simultaneously and proportionally. This requires extremely precise thrust control. These tools are often equipped with adjustable pressure devices to accommodate varying viscosity combinations.

5. Electric and Pneumatic Technologies: Meeting Extreme High-Pressure Requirements

In projects such as large curtain walls and bridge joints, manual extrusion sealant tools (caulking guns) for cartridge use are no longer able to meet the efficiency and pressure requirements. Therefore, electric or pneumatic extrusion sealant tools (caulking guns) for cartridge use have emerged. These devices use a motor or compressed air to drive a piston, providing continuous, stable high-pressure output and capable of reaching hundreds of kilograms of thrust, making them easy to use with ultra-high-viscosity sealants. More importantly, the electric extrusion sealing tool (caulking gun) for cartridge use can be equipped with stepless speed regulation and a pressure feedback system, automatically adjusting output power based on material viscosity, achieving "intelligent caulking." This ensures construction quality while preventing equipment overload and damage.

From household tiles to iconic city facades, the evolution of the extruction sealant tool(caulking gun) for cartridge use witnessed a leap forward in building sealing technology. More than just a simple "caulking tool," it is a precision device that integrates mechanical design, materials science, and engineering manufacturing. Thanks to its reinforced structure, high-strength components, reliable sealing, and upgraded power, the modern extruction sealant tool(caulking gun) for cartridge use can withstand the dual challenges of high pressure and high viscosity with unwavering stability, ensuring every joint is strong, beautiful, and durable.

1. Structural Design: Enhanced Force Transfer and Improved Thrust Efficiency

The core task of cartridge-based extrusion sealant tools (caulking guns) is to smoothly eject high-viscosity colloids from cartridges. High-viscosity materials have high flow resistance, requiring significantly more thrust than standard latex or low-viscosity caulking agents. To this end, professional-grade extrusion sealing tools (caulking guns) for cartridges generally utilize a high-strength mechanical lever structure. This scientifically designed lever ratio amplifies the operator's manual force several times.

2. Key Components: High-hardness Materials Resist Wear and Deformation

Long-term use of highly viscous materials can cause severe wear on the internal components of an extrusion sealing tool (caulking gun) for cartridges, particularly the push rod and plunger tip. Therefore, high-end extrusion sealing tools (caulking guns) for cartridges generally utilize hardened steel push rods or ceramic plunger tips. These materials have a high surface hardness (reaching HRC60 and above), are wear- and corrosion-resistant, and maintain a smooth surface even when pushing through abrasive caulk for extended periods, reducing friction and preventing "sticking." Furthermore, the gun frame is often reinforced with high-strength aluminum alloy or engineering plastic, ensuring lightweight while providing sufficient bending and compression resistance. Some curtain wall-grade electric extrusion sealing tools (caulking guns) for cartridge use even feature all-metal bodies to withstand the intense working conditions of construction sites.

3. Sealing System: Preventing High-Pressure Leakage and Ensuring Stable Pressure

Highly viscous materials often require high pressure for successful extrusion. Any pressure leakage not only affects the uniformity of the adhesive but can also cause backflow or dripping. Therefore, the sealing system of the extrusion sealing tool (caulking gun) for cartridge use is crucial.

4. Cartridge Compatibility: Optimizing Volume and Inner Diameter to Reduce Flow Resistance

The performance of an extrusion sealing tool (caulking gun) for cartridge use is closely related to the cartridge used. For high-volume, high-viscosity applications like curtain wall sealing, standard 310ml rigid aluminum tubes or plastic cartridges are typically used. Their smooth inner wall and uniform dimensions perfectly match the push rod of the extrusion sealing tool (caulking gun) for cartridge use, reducing frictional resistance. In addition, some specialized extrusion sealant tools (caulking guns) for cartridge use support two-component adhesive cartridges (such as epoxy AB adhesive). They feature a built-in static mixer and a synchronized push mechanism in the gun body, ensuring the two high-viscosity materials are extruded and mixed simultaneously and proportionally. This requires extremely precise thrust control. These tools are often equipped with adjustable pressure devices to accommodate varying viscosity combinations.

5. Electric and Pneumatic Technologies: Meeting Extreme High-Pressure Requirements

In projects such as large curtain walls and bridge joints, manual extrusion sealant tools (caulking guns) for cartridge use are no longer able to meet the efficiency and pressure requirements. Therefore, electric or pneumatic extrusion sealant tools (caulking guns) for cartridge use have emerged. These devices use a motor or compressed air to drive a piston, providing continuous, stable high-pressure output and capable of reaching hundreds of kilograms of thrust, making them easy to use with ultra-high-viscosity sealants. More importantly, the electric extrusion sealing tool (caulking gun) for cartridge use can be equipped with stepless speed regulation and a pressure feedback system, automatically adjusting output power based on material viscosity, achieving "intelligent caulking." This ensures construction quality while preventing equipment overload and damage.

From household tiles to iconic city facades, the evolution of the extruction sealant tool(caulking gun) for cartridge use witnessed a leap forward in building sealing technology. More than just a simple "caulking tool," it is a precision device that integrates mechanical design, materials science, and engineering manufacturing. Thanks to its reinforced structure, high-strength components, reliable sealing, and upgraded power, the modern extruction sealant tool(caulking gun) for cartridge use can withstand the dual challenges of high pressure and high viscosity with unwavering stability, ensuring every joint is strong, beautiful, and durable.