How does a caulking gun allow for easy, even application of sealant with one hand?

Release Time : 2025-12-18

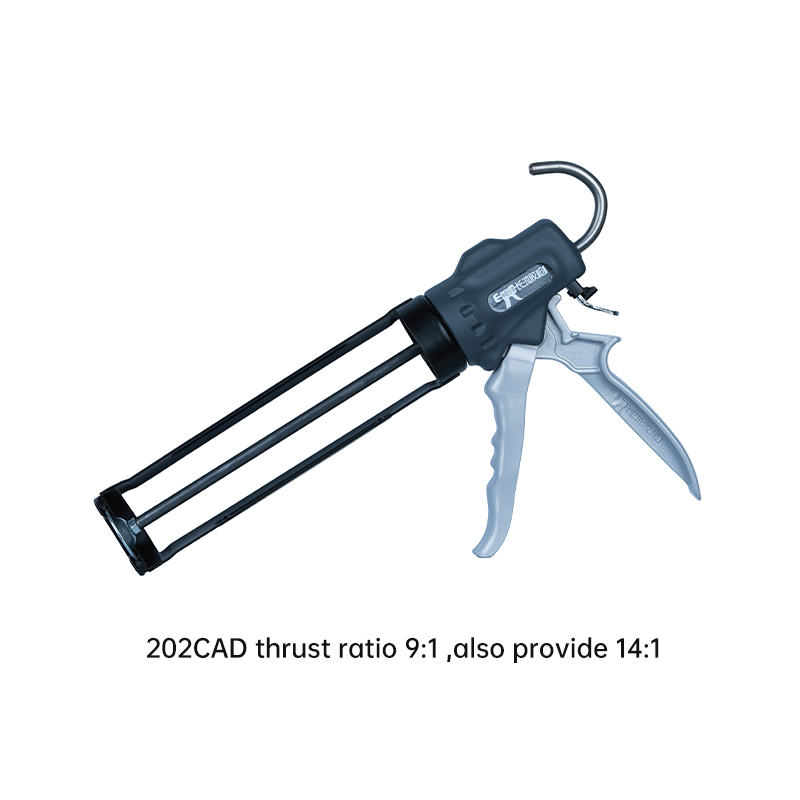

Sealant is used almost everywhere in home renovations, door and window installations, and bathroom grouting. However, many people encounter difficulties when trying to squeeze the glue tube by hand, often experiencing uneven, intermittent, or even impossible glue application—wasting material and resulting in uneven, misaligned glue lines, severely impacting aesthetics and sealing performance. A well-designed caulking gun (also called a glue gun or caulking applicator) allows ordinary people to easily, smoothly, and evenly apply sealant with just one hand.

The key lies in the combination of its lever-based force-saving principle and precise transmission structure. At the core of the caulking gun is a mechanical lever system: when the user grips the handle, the force is amplified through the fulcrum, pushing the push rod forward smoothly. This design significantly reduces the required hand force, allowing for easy and continuous glue application even with high-viscosity silicone or polyurethane sealants. More importantly, a high-quality caulking gun features a smooth, uninterrupted push rod stroke, ensuring a uniform flow of adhesive from the nozzle and preventing bulges or broken threads caused by inconsistent flow.

To achieve uniformity, the adhesive dispensing control mechanism is crucial. High-end caulking guns typically feature adjustable push levels or damping devices, allowing users to fine-tune the dispensing resistance based on the adhesive's consistency, thus precisely controlling the flow rate. Crucially, a back-suction anti-drip function is also essential—the internal spring or negative pressure structure slightly pulls back the push rod the moment the handle is released, cutting off the adhesive flow and preventing the adhesive from sag due to gravity and forming "strings" or drips at the end. This detail not only keeps the work surface clean but also makes finishing the edges cleaner and neater.

Furthermore, the ergonomic design greatly enhances the comfort and stability of one-handed operation. The handle is shaped to fit the curve of the palm and covered with non-slip soft rubber, reducing fatigue even during extended use. The trigger position matches the natural curvature of the fingers, resulting in more natural force application. The overall balanced center of gravity prevents the gun from wobbling during application, helping to create straight, continuous glue lines. This one-handed control is especially valuable in scenarios requiring tilting the head up (such as ceiling seams) or operating in narrow corners.

Universal compatibility and detailed optimizations further enhance practicality. Most caulking guns use a standard barrel base, compatible with various common sealing glue cartridges on the market. The rotating nozzle design allows users to freely adjust the glue dispensing direction according to the application angle, easily handling complex locations such as inside window frames and corner junctions. A one-button release allows for quick ejection of the empty cartridge for easy replacement, improving overall efficiency.

It's worth mentioning that the value of a caulking gun lies not only in its "effortless" nature but also in providing non-professionals with near-artisan-level application results. A uniform line of sealant signifies better sealing—effectively preventing moisture penetration, mold growth, or air leaks; a clean appearance also eliminates the hassle of later repairs. Whether sealing bathroom tile gaps, installing kitchen countertops, or applying weather-resistant sealant to new windows, a good caulking gun makes the entire process efficient, clean, and rewarding.

Ultimately, the brilliance of a caulking gun lies in integrating complex physical principles into a simple, everyday tool. It's unassuming yet quietly resolves many of the pain points of manual caulking; it's inexpensive yet significantly improves the quality and experience of home repairs. When a thread of sealant smoothly falls into the center of the joint, with neat edges and consistent thickness, at that moment, you feel not only the satisfaction of completing the task but also the gentle empowerment of life by the tool—because true convenience is never about replacing craftsmanship, but about enabling everyone to do things better with ease.

The key lies in the combination of its lever-based force-saving principle and precise transmission structure. At the core of the caulking gun is a mechanical lever system: when the user grips the handle, the force is amplified through the fulcrum, pushing the push rod forward smoothly. This design significantly reduces the required hand force, allowing for easy and continuous glue application even with high-viscosity silicone or polyurethane sealants. More importantly, a high-quality caulking gun features a smooth, uninterrupted push rod stroke, ensuring a uniform flow of adhesive from the nozzle and preventing bulges or broken threads caused by inconsistent flow.

To achieve uniformity, the adhesive dispensing control mechanism is crucial. High-end caulking guns typically feature adjustable push levels or damping devices, allowing users to fine-tune the dispensing resistance based on the adhesive's consistency, thus precisely controlling the flow rate. Crucially, a back-suction anti-drip function is also essential—the internal spring or negative pressure structure slightly pulls back the push rod the moment the handle is released, cutting off the adhesive flow and preventing the adhesive from sag due to gravity and forming "strings" or drips at the end. This detail not only keeps the work surface clean but also makes finishing the edges cleaner and neater.

Furthermore, the ergonomic design greatly enhances the comfort and stability of one-handed operation. The handle is shaped to fit the curve of the palm and covered with non-slip soft rubber, reducing fatigue even during extended use. The trigger position matches the natural curvature of the fingers, resulting in more natural force application. The overall balanced center of gravity prevents the gun from wobbling during application, helping to create straight, continuous glue lines. This one-handed control is especially valuable in scenarios requiring tilting the head up (such as ceiling seams) or operating in narrow corners.

Universal compatibility and detailed optimizations further enhance practicality. Most caulking guns use a standard barrel base, compatible with various common sealing glue cartridges on the market. The rotating nozzle design allows users to freely adjust the glue dispensing direction according to the application angle, easily handling complex locations such as inside window frames and corner junctions. A one-button release allows for quick ejection of the empty cartridge for easy replacement, improving overall efficiency.

It's worth mentioning that the value of a caulking gun lies not only in its "effortless" nature but also in providing non-professionals with near-artisan-level application results. A uniform line of sealant signifies better sealing—effectively preventing moisture penetration, mold growth, or air leaks; a clean appearance also eliminates the hassle of later repairs. Whether sealing bathroom tile gaps, installing kitchen countertops, or applying weather-resistant sealant to new windows, a good caulking gun makes the entire process efficient, clean, and rewarding.

Ultimately, the brilliance of a caulking gun lies in integrating complex physical principles into a simple, everyday tool. It's unassuming yet quietly resolves many of the pain points of manual caulking; it's inexpensive yet significantly improves the quality and experience of home repairs. When a thread of sealant smoothly falls into the center of the joint, with neat edges and consistent thickness, at that moment, you feel not only the satisfaction of completing the task but also the gentle empowerment of life by the tool—because true convenience is never about replacing craftsmanship, but about enabling everyone to do things better with ease.