How does a caulking gun significantly reduce the force required for manual application of sealant through its lever design?

Release Time : 2025-12-31

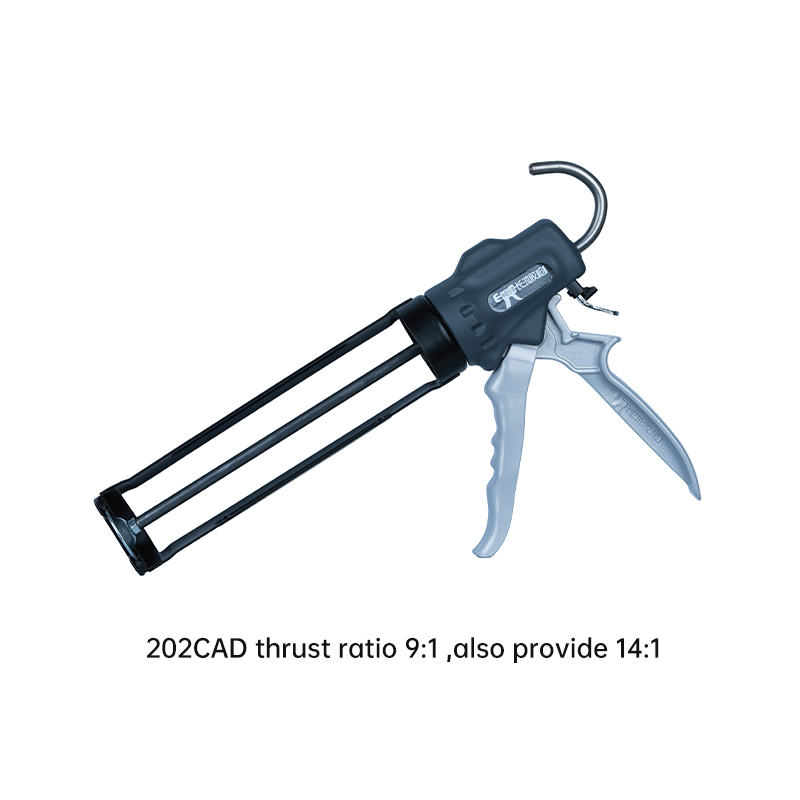

In construction, home repair, and industrial sealing operations, a caulking gun is an indispensable tool for handling cartridge sealant. Faced with the strong resistance generated by high-viscosity sealant within a confined cartridge, relying solely on direct finger pressure is not only inefficient but also prone to hand fatigue and even injury. The reason modern caulking guns easily overcome this challenge lies in their ingenious use of the lever principle—through a scientifically designed mechanical structure, they amplify the user's small grip force into a powerful pushing force, achieving a "small effort, big result" operating experience.

1. Lever Ratio: The Key Mechanism for Force Amplification

The effort-saving effect of a caulking gun primarily stems from the lever ratio design between its trigger and push rod. When the user pulls the trigger, the trigger acts as the power arm, rotating around the fulcrum, driving the push rod forward to advance the cartridge piston. Caulking guns typically employ a combination of a longer power arm and a shorter resistance arm, creating a high leverage ratio. This means that users can generate several times, or even ten times, the thrust at the pusher end with only a small amount of hand force. For example, a light grip on the trigger is as easy as unscrewing a bottle cap, yet sufficient to steadily extrude a viscous structural adhesive like peanut butter, greatly lowering the application threshold.

2. Double Linkage or Multi-Stage Transmission: Further Optimizing Force Transmission Efficiency

In addition to the basic lever, caulking guns often incorporate double linkage, gear-assisted, or pulley-type transmission mechanisms. These designs transform the arc-shaped motion of the trigger into a more linear thrust output, reducing energy loss and making force transmission smoother. Some professional models also employ a "progressive" lever curve—the initial pull is gentle for easy control of the initial adhesive amount, gradually increasing the thrust as the stroke deepens, adapting to the resistance changes of the adhesive from rest to flow. This intelligent force feedback mechanism ensures both precision in fine work and maintains efficient output during continuous adhesive application.

3. Ergonomic Handle Layout: Making Effortless Application More "Convenient"

Effortless application depends not only on the mechanical structure but also on the rationality of human-machine interaction. The caulking gun's handle curvature conforms to the natural grip of the hand, and the trigger position is moderate, preventing excessive wrist bending. The handle surface is often covered with non-slip soft rubber, ensuring a stable grip even with wet hands or while wearing gloves. More importantly, the fulcrum position has been repeatedly tested and optimized to ensure that the direction of force is aligned with the actuator axis, preventing lateral force from causing jamming or cartridge misalignment. This "comfortable" design reduces user fatigue during long periods of use, truly achieving "effortless and worry-free" operation.

4. Low-friction guiding system: reducing internal energy loss

Even the most efficient lever will have reduced output if internal friction is too high. The caulking gun's actuator rail, slider, and guide groove are all precision-machined and combined with self-lubricating materials or smooth coatings to ensure smooth and unobstructed movement. The actuator plate fits perfectly against the bottom of the cartridge, distributing force evenly and preventing localized slippage or idle travel. These details collectively ensure that almost all the amplified force of the lever is used to push the cartridge, rather than being consumed by mechanical internal friction.

5. Labor-Saving Value in Practical Applications

In real-world construction scenarios, the labor-saving design offers multiple advantages: workers can complete high-level tasks such as applying sealant to ceilings and sealing window frames with one hand, without additional support; female users or those with weaker physical strength can easily handle high-viscosity structural adhesives; and in projects requiring continuous sealant application over hundreds of meters, it significantly reduces the risk of occupational injuries. More importantly, the stable and controllable dispensing process reduces adhesive waste and trimming time, improving overall construction quality and efficiency.

The caulking gun's labor-saving lever design is a perfect example of the combination of mechanical intelligence and practical needs. It doesn't rely on electricity or complex electronic components; through its ingenious physical structure, it transforms the most primal human grip strength into efficient, precise, and durable sealing power. In this era that values both efficiency and human-centered design, a good caulking gun is not just a tool, but also a gentle protector of the worker's hands.

1. Lever Ratio: The Key Mechanism for Force Amplification

The effort-saving effect of a caulking gun primarily stems from the lever ratio design between its trigger and push rod. When the user pulls the trigger, the trigger acts as the power arm, rotating around the fulcrum, driving the push rod forward to advance the cartridge piston. Caulking guns typically employ a combination of a longer power arm and a shorter resistance arm, creating a high leverage ratio. This means that users can generate several times, or even ten times, the thrust at the pusher end with only a small amount of hand force. For example, a light grip on the trigger is as easy as unscrewing a bottle cap, yet sufficient to steadily extrude a viscous structural adhesive like peanut butter, greatly lowering the application threshold.

2. Double Linkage or Multi-Stage Transmission: Further Optimizing Force Transmission Efficiency

In addition to the basic lever, caulking guns often incorporate double linkage, gear-assisted, or pulley-type transmission mechanisms. These designs transform the arc-shaped motion of the trigger into a more linear thrust output, reducing energy loss and making force transmission smoother. Some professional models also employ a "progressive" lever curve—the initial pull is gentle for easy control of the initial adhesive amount, gradually increasing the thrust as the stroke deepens, adapting to the resistance changes of the adhesive from rest to flow. This intelligent force feedback mechanism ensures both precision in fine work and maintains efficient output during continuous adhesive application.

3. Ergonomic Handle Layout: Making Effortless Application More "Convenient"

Effortless application depends not only on the mechanical structure but also on the rationality of human-machine interaction. The caulking gun's handle curvature conforms to the natural grip of the hand, and the trigger position is moderate, preventing excessive wrist bending. The handle surface is often covered with non-slip soft rubber, ensuring a stable grip even with wet hands or while wearing gloves. More importantly, the fulcrum position has been repeatedly tested and optimized to ensure that the direction of force is aligned with the actuator axis, preventing lateral force from causing jamming or cartridge misalignment. This "comfortable" design reduces user fatigue during long periods of use, truly achieving "effortless and worry-free" operation.

4. Low-friction guiding system: reducing internal energy loss

Even the most efficient lever will have reduced output if internal friction is too high. The caulking gun's actuator rail, slider, and guide groove are all precision-machined and combined with self-lubricating materials or smooth coatings to ensure smooth and unobstructed movement. The actuator plate fits perfectly against the bottom of the cartridge, distributing force evenly and preventing localized slippage or idle travel. These details collectively ensure that almost all the amplified force of the lever is used to push the cartridge, rather than being consumed by mechanical internal friction.

5. Labor-Saving Value in Practical Applications

In real-world construction scenarios, the labor-saving design offers multiple advantages: workers can complete high-level tasks such as applying sealant to ceilings and sealing window frames with one hand, without additional support; female users or those with weaker physical strength can easily handle high-viscosity structural adhesives; and in projects requiring continuous sealant application over hundreds of meters, it significantly reduces the risk of occupational injuries. More importantly, the stable and controllable dispensing process reduces adhesive waste and trimming time, improving overall construction quality and efficiency.

The caulking gun's labor-saving lever design is a perfect example of the combination of mechanical intelligence and practical needs. It doesn't rely on electricity or complex electronic components; through its ingenious physical structure, it transforms the most primal human grip strength into efficient, precise, and durable sealing power. In this era that values both efficiency and human-centered design, a good caulking gun is not just a tool, but also a gentle protector of the worker's hands.